|

|

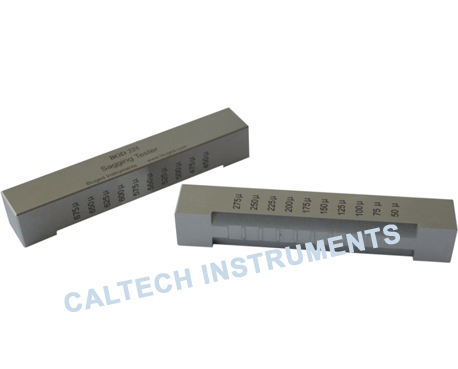

| Sagging Tester |

|

|

|

BGD 225 Sagging Tester produced by our company is in accordance with the specification of ASTM D 4400 and ASTM D 373. They are made of corrosion resistant stainless steel, the width of application is 75mm at 6mm per sagging thickness, and the gaps are being separated by a 1mm space as a marking on each sagging for distinctive identification of each sagging.

They are applicable to determine the relative sag resistance of a series of paints in order to provide the technical parameters for the paint application on site. |

| |

| Main Technical Parameters: |

|

Clearance ranges: |

| |

| Ordering information |

BGD 225/1 |

BGD 225/2 |

BGD 225/3 |

BGD 225/4 |

BGD 225/5 |

| RANGE |

50-275μm |

250-475μm |

450-675μm |

650-875μm |

850-1,075μm |

|

|

Difference between adjacent two notches:25μm |

|

Overall dimension:120×20×20mm(length by width by height) |

|

Weight:0.5Kg |

|

| |

| Manual: |

| Drawdown the coatings on a material(glass, test chart or board)using the appropriates sagging Thickness Gauges, then place the coated material at vertical position(90º)to the platform(eg: table).Allow 10 to 30 minutes(depending on the viscosity)for the coatings to sag under gravity. Check out the coating thickness without the sagging effect and the next coating thickness with the sagging effect. With that information, the recommended coating thickness is between the 2 layers of coatings. |

| |

|

|

| |

|